Toro Recycler 22 has become a favorite auto drive push mower among gardeners and homeowners worldwide by providing quality service in a consistent manner. Utilizing the power of a 9.8 N.m Gross Torque Briggs & Stratton® EXi 163cc engine and a 22 inch (56 centimeter) deck, this mower provides the users with clean and even cut grass every time.

Although this amazing piece of lawn care equipment has made mowing the lawn easy and affordable, users can run into various problems with time and usage. One of the most common problems is the mower failing to start which can be caused by issues in one or multiple components on the mower.

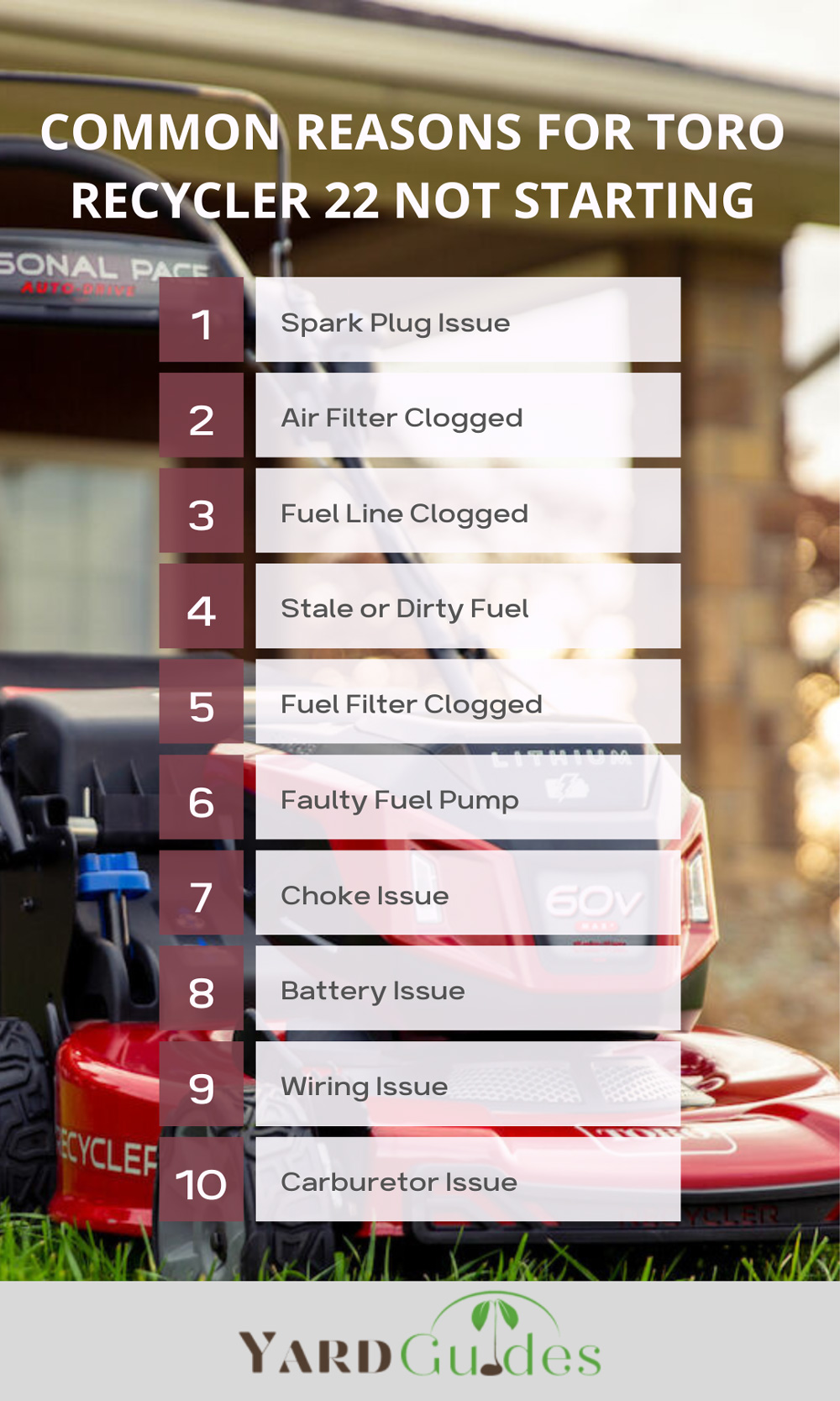

The most common reasons why Toro Recycler 22 fails to start are faulty spark plug, stale or dirty fuel, storing the mower for a long time, faulty carburetor, weak or dead battery, faulty wirings, and many more.

Users can fix these problems easily by following the correct guidelines and using the right tools. Keeping all the parts of the mower clean and in pristine condition will prevent the user from facing this problem.

What are the Common Reasons for Toro Recycler 22 Not Starting?

The most common reasons for Toro Recycler 22 not starting are discussed below with exact solutions.

Spark Plug Issue

Faulty spark plug is one of the most common reasons behind the mower failing to start. Spark plug takes power from the battery when the mower is started and uses that electricity to create a spark that ignites the gas in the cylinders of the engine and starts the combustion process. Mower will fail to start if the electrodes of the spark plug get damaged or bent, accumulate carbon, get corroded, or the gap between them gets widened. Spark plug is also not functioning properly if it feels too dry or too wet when you pull it out.

Solution: Remove the spark plug and check it with a multimeter to see if the electrodes are carrying electricity properly. Clean all the dust and carbon build-up from the electrodes. Fix the electrode gap if it gets too wide or too narrow. Replace the spark plug entirely if it gets too badly damaged. It will cost you $5-$15 for a spare spark plug.

Air Filter Clogged

Clogged air filters can also be the reason behind your mower failing to start. Air filters work to provide the carburetor with clean air that it mixes with gasoline to provide the perfect mixture to the engine manifold for powering the engine. Clogged air filters prevent clean air from flowing properly and can stop the engine from starting.

Solution: Take out the air filter cover and clean the inside thoroughly. Change the filters entirely if they get too dirty. Screw everything back to its place after you’re finished cleaning or replacing the air filters. You can get an air filter for $10-$15.

Fuel Line Clogged

Fuel lines can get clogged because of carbon build-up, debris accumulation, faulty fuel filter, and dirty or stale fuel. Fuel pump will fail to pump fuel from the gas tank to the carburetor if the fuel line is clogged and thus the mower will fail to start.

Solution: Remove all the hose screws from the connecting points of the fuel lines and drain all the fuel. Keep a container or bowl below the fuel lines to prevent fuel from spilling everywhere. Clean the fuel line thoroughly and then check these tubes with a pressure gauge for leaks. Change the fuel lines if they have sprung a leak. Check the connecting points to see if they are closed tightly.

Stale or Dirty Fuel

Stale of dirty fuel in the fuel tank and the fuel line is one of the most common reasons behind the mower failing to start. Dirty or stale fuel does not possess the capability to combust properly in the engine cylinder and prevents the engine from starting. Stale fuel issue arises if fuel is left in the fuel tank for a long period without proper stabilizing agents.

Solution: Drain all the fuel from the tank and the fuel lines completely. You can drain the fuel tank by removing the drain valve on the bottom of the fuel tank. Clean the fuel tank thoroughly if there is any debris or carbon build up in it. Fill it with fresh gasoline. Use high grade fuel stabilizers if you wish to store the mower with fuel for longer periods of time.

Fuel Filter Clogged

Fuel filter works to filter out any unwanted substance that might get into the carburetor with the fuel. Fuel filters are constantly getting dirty and clogged up because of dirt and debris build up. Clogged up fuel filters prevent fuel from flowing through the fuel lines and into the carburetor and then the engine.

Solution: Clean, repair, or replace the fuel filter. A fuel filter will cost you $5-$15.

Faulty Fuel Pump

Fuel pump creates a vacuum in its chambers and pulls out fuel from the fuel tank and supplies it to the carburetor. Fuel pumps make a low humming noise while starting. Fuel pumps can become faulty if the valves malfunction or if the pump fails to take power from the battery.

Solution: Clean the valves of the fuel pump if any dust, debris, or carbon build up inside them. Replace the fuel pump entirely if it becomes completely malfunctional. A new fuel pump will cost $15-$30.

Choke Issue

Choke helps the carburetor to supply gasoline rich fuel and air mixture to the engine manifold to start the engine. Automatic choke systems are connected with spring mechanisms to ensure that choke turns on every time the vehicle is started. Engine will fail to start properly if the choke is off or not functioning properly.

Solution: Check if the choke lever is connected with the spring mechanism and is automatically engaging when you turn on the mower. Fix or replace the lever if it gets too badly damaged.

Battery Issue

Weak or dead battery will prevent the mower from starting properly as power will not be transferred from the battery to the spark plug to start the combustion cycle.

Solution: Charge the battery with a charger until the charge level is full. Use a cable jumper and another vehicle like a car to jump start the mower if you are in a hurry. Change the battery if it fails to take charge and has become completely dead. A replacement battery will cost you approximately $80.

Wiring Issue

Mower might also fail to start because of wiring issues that prevent power from properly flowing from the battery to other parts of the mower. Electrical wires can fall subject to corrosion, short circuits, and regular wear and tear.

Solution: Check all of the wirings with a multimeter to see if they are carrying power properly. Repair any short circuits or disconnected wires you find. Replace the wires if they get beyond repair.

Carburetor Issue

Carburetor mixes fuel and air in the correct proportion and supplies this mixture into the engine manifold to start the combustion cycle. Carburetors can get dirty with time and usage and will require cleaning.

Solution: Take out the carburetor and clean it thoroughly of any carbon build-up, dirt, dust, or debris accumulation. Change the carburetor entirely if it is badly damaged. Spare carburetor will cost $15-$25.

Why toro recycler 22 won’t start after the winter?

Toro recycler 22 will not start after winter because of stale or dirty fuel in the fuel tank. Fuel loses its efficiency if it is stored for a long period of time without proper fuel stabilizer.

Solution: Drain all the stale fuel from the fuel tank and fill it with fresh and clean gasoline. Use quality fuel stabilizers with gasoline if you wish to store the mower for an extended period of time.

How to Prevent Toro Recycler 22 Not Starting Problem?

Follow these procedures to prevent the problem of Toro Recycler 22 not starting.

- Regularly charge the battery and check battery health.

- Keep the spark plug clean.

- Regularly clean the fuel tank, fuel lines, air filter, fuel filter, carburetor, the deck, and the blades.

- Always use clean and fresh gasoline with the proper amount of engine oil.

- Check the choke lever and make sure it is functioning properly.